Screenings Conveying

CCS – Horizontal and Inclined Shaftless Screw Conveyor

The transport of the screenings using shaftless screw conveyorsis becomingmore widespread. The advantages ofthissystemare numerous, ifcompared to the traditional screwshaft.

The transport of the screenings using shaftless screw conveyorsis becomingmore widespread. The advantages ofthissystemare numerous, ifcompared to the traditional screwshaft.

The principle of operation of the conveyors with shaftless spiral is extremely simple, and beacuse of this simplicity, it is the most relible method for transporting solids or semi-solids (screening, sludge or sand), having different sizes and irregular sizes. The shaftless spiral roates ina liner of plastic material, high molecular density, or in steel bars (depending on the type of products to be transported). The absence of intermediate supports or endbearing makes ot possible realizations of shaftless screw conveyors up to 30 meters in one piece. The speed of rotation of the spiral changes as a funcation of the lenght, the diameter and the type of product to be transported. The shaftless screw conveyors can be realized with external U-Shaped chute ot tubular version. The inclination can be from 0 horizontal and / or up to 90 vertical. Filling % is generally very low and this is a futher advantage of the shaftless screw conveyors compared to the traditional shafted (with shaft).

| Capacity table for screenings and / or sludge | ||||

| SCREENINGS | SLUDGE | |||

| 0°- 15° | 16° - 90° | 0°- 15° | 16° - 90° | |

| DN 150 | 0.5 | 0.3 | 1.5 | 1 |

| DN 200 | 1 | 0.7 | 3.3 | 1.5 |

| DN 250 | 2.5 | 1.6 | 6.5 | 4 |

| DN 300 | 3.7 | 2 | 11 | 6.5 |

| DN 350 | 5.2 | 2.5 | 16 | 9 |

| DN 400 | 7.5 | 4 | 20 | 12 |

| DN 500 | 15 | 8.2 | 41 | 25 |

| DN 600 | 20 | 16 | 52 | 35 |

CCS/V – Vertical Shaftless Screw Conveyor

| Inclination | Screenings | Studge |

| DN 150 | 0.3 | 1 |

| DN 200 | 0.7 | 1.5 |

| DN 250 | 1.6 | 4 |

| DN 300 | 2 | 6.5 |

| DN 350 | 2.5 | 9 |

| DN 400 | 4 | 12 |

| DN 500 | 8.2 | 25 |

| DN 600 | 16 | 35 |

Shaftless screw conveyors CCS can be manufactured in vertical installation (CCS-V). This is a great advantage to reduce system footprint necessary and to lift up screening/ Sludge until 20mt hright. Execution inside an external pip or two U troughts bolted together. Vertical shaftless screw conveyor CCS-V can be installed with gearmotoe pushing or pulling, it depends from the material to convey and the site requirements.

Shaftless screw conveyors CCS can be manufactured in vertical installation (CCS-V). This is a great advantage to reduce system footprint necessary and to lift up screening/ Sludge until 20mt hright. Execution inside an external pip or two U troughts bolted together. Vertical shaftless screw conveyor CCS-V can be installed with gearmotoe pushing or pulling, it depends from the material to convey and the site requirements.

Screenings Treatment

CP - Shaftless Spiral Conveyor and compactor

Working Principle

The CP Shaftless screw compactor combines two operations: conveying, compacting.

The machine consists of three section: the draining section, usually placed before the hopper where the majority of the water is discharged; the conveying section that moves the material to the compacting/ dewatering section, where both the volume and the weight reducation take place (up to 50%).

The machine consists of three section: the draining section, usually placed before the hopper where the majority of the water is discharged; the conveying section that moves the material to the compacting/ dewatering section, where both the volume and the weight reducation take place (up to 50%).

The screw is usually connected directly to the drive system. The working range of the machine is 5° tp 35°.

Manufacturing Features

Screw: High Strength carbon steel or stainless steel AISI 304/ 316

Structure: Galvanized iron or stainless steel AISI 304/ 316

Length: The maximum length depends on the overall specifications (power and diameter) and can ne up to 20 meters.

Trough Protection: HUPE Liner or bolted stainless steel wearing bars.

Drive: The maximum power depends on the inclination, the flow rate and the length.

| Model | A(mm) | L(mm) | B(mm) | inclination | Nominal Flowrate (m3/ h) |

| CP 200 | 350 | 1000-7000 | 500 | 5° - 30° | 2 |

| CP 300 | 550 | 1000-9000 | 700 | 5° - 30° | 5 |

| CP 400 | 700 | 2000-12000 | 950 | 5° - 30° | 8 |

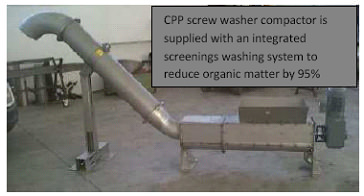

CPP - Screw Press With Screenings Washings

Working Principle

The CCP screw compactor combines two operations:

washing and compaction of screenings.

It can be placed directly under the screen or fedwith a convyor.

The machine consists of inlet hopper connected with a tubular section (draining section) with aperforted bottom for water discharge; the hoppercan be equipped with a supplementary washingsystem in order to increase the organic matter removal efficiency.

Along the transport section, a nozzle systemper forms the screenings washing, untill the compacting section. The compacting counterforce is realized by meansof a "truck shapped discharge tube.

The high compaction rate and the screenings washing reduces disposal costs and odour problems.

Manufacturing Features

Screw: High Strength carbaon steel orstainless

steel AISI 304/ 316

Structure: Stainless steel AISI 304/ 316

| Model | Screw | Hopper | Nominal Flowrate (m/h) |

| CPP | DN 200 | Variable | 2 |

| CPP | DN 300 | Variable | 3 |